ERP for Food and Beverage Manufacturers in Canada

Real-time visibility into costs, inventory, compliance, and margins — built for the complexity of erp for food and beverage operations.

- Batch & lot traceability

- Shelf-life & expiry date control

- Accurate production & landed costing

- Compliance-ready financial reporting

Operational performance overview

- Real-time visibility across inventory, production, and finance

- Batch-level traceability with compliance-ready reporting

- Accurate cost allocation by product, lot, and production run

- Multi-entity financial consolidation in real time

INVENTORY ACCURACY

98%

WASTE REDUCTION

-12%

MARGIN VISIBILITY

+8%

25+ Years

Experience

ERP Implementation

500+

Trusted By

Organizations Nationwide

Certified

Partnership

Sage & Acumatica Partner

Proven

Expertise

Canadian Compliance

ERP Challenges in the Food and Beverage Industry

Traditional accounting software struggles to support the realities of food and beverage manufacturing.

Tight Margins & Rising Costs

Food and beverage businesses operate with thin margins. Without accurate costing and margin visibility, profitability is often assumed rather than measured.

Shelf Life & Waste Risk

Poor expiry control leads to unnecessary waste, recalls, and write-offs — directly impacting cash flow.

Compliance Requirements

Regulations such as CFIA, FSMA, and customer audit requirements demand accurate, accessible traceability data at all times.

Disconnected Systems

Many companies rely on a mix of accounting tools, spreadsheets, production systems, and third-party inventory software.

Not sure if your current systems can handle these challenges?

Core ERP Capabilities for Food & Beverage

Build a resilient operation with features designed specifically for your industry.

Batch & Lot Traceability

A specialized ERP enables full end-to-end traceability — from supplier to customer — ensuring rapid response to recalls, audits, and quality issues.

Business Impact

- Faster recall response times

- Reduced regulatory risk

- Increased customer confidence

Recipe & Formula Management

Manage recipes, formulas, and versions while automatically calculating ingredient usage, yield variance, and cost impact.

Business Impact

- Accurate product costing

- Controlled recipe changes

- Improved consistency

Production & Landed Costing

Unlike generic systems, calculate true cost per batch, including labor, overhead, freight, and yield variance.

Business Impact

- Accurate margin analysis

- Better pricing decisions

- Improved profitability

Quality Management & Compliance

Built-in quality workflows allow organizations to document inspections, certifications, and audit trails.

Business Impact

- Audit readiness at all times

- Reduced manual documentation

- Lower compliance risk

Shelf-Life & Expiry Control

Native FIFO and FEFO logic ensures inventory is consumed and shipped in the optimal sequence.

Business Impact

- Reduced waste and write-offs

- Improved inventory turns

- Better service levels

Inventory Forecasting

Analyze historical demand and seasonality to improve purchasing and production planning.

Business Impact

- Reduced stockouts

- Lower excess inventory

- Improved cash flow

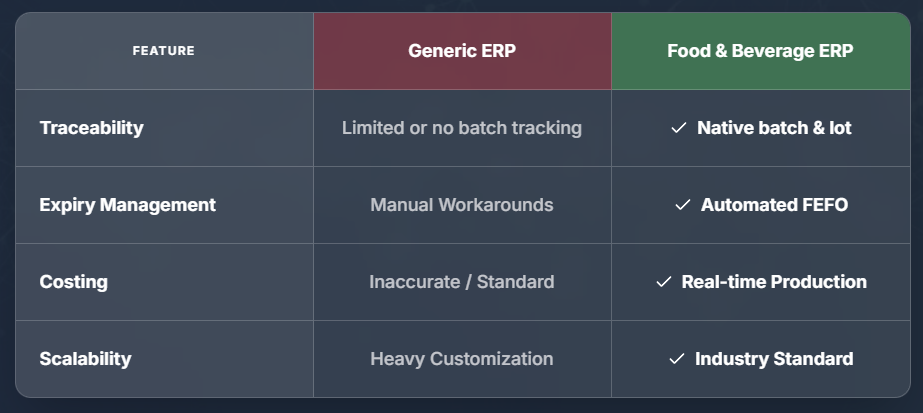

Why Generic ERP Systems Fail

Generic systems were not built to handle perishability, compliance, and production complexity.

Feature

Generic ERP

Food & Beverage ERP

Traceability

Limited or no batch tracking

- Native batch & lot

Expiry Management

Manual Workarounds

- Automated FEFO

Costing

Inaccurate / Standard

- Real-time Production

Scalability

Heavy Customization

- Industry Standard

ERP for Food and Beverage for Every Stage of Growth

We partner with leading ERP providers to implement the right solution for your specific needs.

Ideal for complex food manufacturing and distribution operations with multi-site, multi-country, and advanced supply chain requirements.

Best Suited For:

Process Manufacturing

Multi-location Operations

Complex Compliance

Offers flexibility and scalability for growing food and beverage businesses seeking cloud-based operations without per-user licensing.

Best Suited For:

Growing Manufacturers

Cloud-first Organizations

Flexible Models

Best-in-class financial management for multi-entity food and beverage organizations requiring advanced reporting.

Best Suited For:

Finance-driven Orgs

Multi-entity Consolidation

Strong Reporting

Why Food & Beverage Companies Choose IWI Consulting Group

Choosing the right ERP is only half the equation. Successful outcomes depend on implementation expertise. We focus on delivering business value — not just software.

- Deep understanding of food and beverage workflows

- Expertise migrating from legacy and disconnected systems

- Canadian regulatory and financial reporting knowledge

- Long-term post-go-live support

How we help in practice

Manufacturer Case

Reduces inventory waste by improving expiry management

Distributor Case

Improves inventory turns and order fulfillment speed

Multi-Entity Case

Consolidates financials in real time across all locations

Frequently Asked Questions about ERP for Food and Beverage

How long does ERP for Food and Beverage implementation take?

Most projects range from 4 to 9 months depending on complexity. We use a phased approach to ensure value is delivered quickly

Is ERP only for large manufacturers?

No. Modern cloud ERP solutions like Acumatica scale for mid-sized and growing companies, offering enterprise-grade features at an accessible price point.

Is ERP disruptive to operations?

With proper planning, testing, and training, disruption is minimized. Our methodology focuses on business continuity throughout the go-live process.

Can ERP integrate with existing systems?

Yes. Modern ERPs have robust APIs to integrate with specialized production equipment, warehouse management systems (WMS), and third-party logistics platforms.

What is the ROI timeline?

Most organizations see measurable improvements in inventory accuracy, waste reduction, and administrative efficiency within the first year of operation.Most projects range from 4 to 9 months depending on complexity. We use a phased approach to ensure value is delivered quickly

Ready to Gain Control Over Your Operations?

ERP provides the visibility, control, and scalability required to compete in today’s food and beverage industry.

What's included in your Free Assessment?

- Analysis of your current inventory & production workflows

- Identification of compliance & traceability gaps

- Personalized ERP recommendation & roadmap